rod mills selection criterion

rod mills selection criterion A modern approach to the selection of sucker rod pumping Mar 01 2011 The selection pumping mode is based on the application of the selection method proposed and represents the best selection for the CBM wells studied Based on the values of the operational parameters calculated the methodology proposed leads Nov 30, 2018 Contact name:lily Whatsapp: +97 :lily@gmail Rod mills and ball mills are the two most commonly used equipment in grinding equipmentHow to choose Rod mill and ball mill?Rod mills 20 Roller mills 20 Food machinery Fillers 125 Kneading machines 14 Packaging machines 125 Sugar cane crushers 16 a further criterion in coupling selection For this reason the bore capacity has to be checked after having determined the coupling size on basis of the power datarod mills selection criterion eliasbeeckmanedenlRod Mills Selection Criterion Drive Shafts For Industry Stainless steel shafts factory sep 05, 2019 drive shafts, machine shafts, spindles manufactured as per customer requirementwith micron tolerances maintained for bearing diametersRod Mills Selection Criterion Drive Shafts For IndustryApr 15, 2015 Rod and ball milling, using grinding media of known quality, are well established and require much simpler grinding test programs than required for the selection of autogenous grinding mills and circuits Samples for grindability tests should be crushed to about minus 1″What Ore Testing is Required For Mill Selection

Rod Mill an overview ScienceDirect Topics

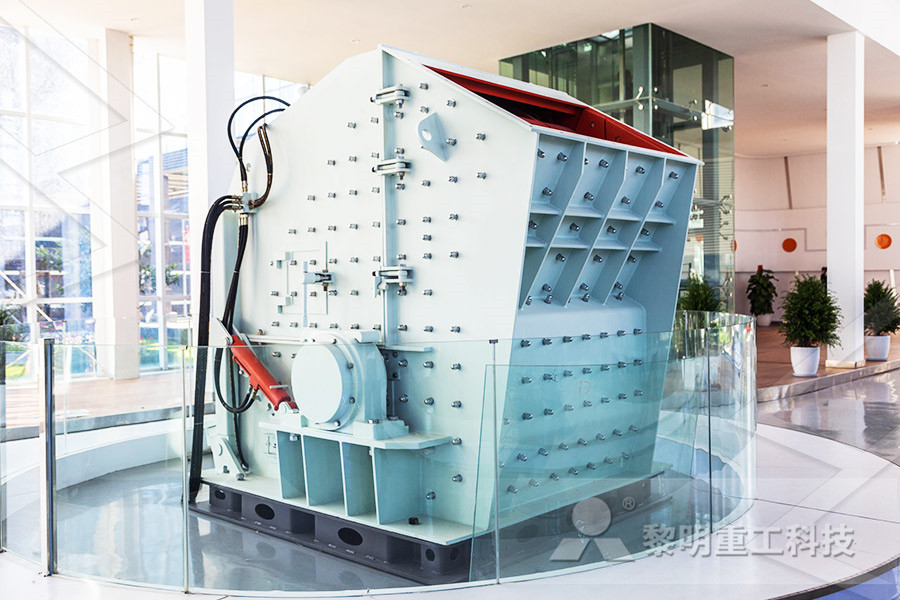

Rod mills are charged initially with a selection of rods of assorted diameters, the proportion of each size being calculated to approximate to a seasoned or equilibrium charge From: Wills' Mineral Processing Technology (Eighth Edition), 2016May 31, 2016 End Peripheral discharge and center peripheral discharge rod mills are described in detail on pages 28 and 29 Feed and discharge heads of Rod Mills are conical in shape providing important advantages over a mill with straight heads 1 They provide the essential feed pocket and also a space for the pulp to squeeze from the rod massRod Mills 911 MetallurgistAutmatic Sand Blaster Machine Rod Mills Selection Criterion Autmatic Sand Blaster Machine Rod Mills Selection Criterion; 10 Amazing Automatic Firewood Processing 10112018 10 Amazing Automatic Firewood Processing Machine, Homemade Modern Wood Cutting Chainsaw Machines Thanks you for watching !Selection Of Rod MillsNov 30, 2018 Contact name:lily Whatsapp: +97 :lily@gmail Rod mills and ball mills are the two most commonly used equipment in grinding equipmentHow to choose Rod mill and ball mill?[Overflow Rod Mills Figure 1 Peripheral Discharge Rod Mills Figures 2 and 3 Compartment Mills Rod and Ball Figure 6 Ball Figure 6a Pebble Mill Figure 6b Overflow Ball Mills Figure 8 Diaphragm (Grate Discharge) Ball Mills Figure 9] I GENERAL MILL DESIGN A Liners The interior surface of grinding mills exposed to grinding media and/or the Selection Of Rod Mills, Ball Mills, Pebble Mills And

Rod mills, how they function Mine

Rod mills are very similar to ball mills, except they use long rods for grinding media The rods grind the ore by tumbling within the the mill, similar to the grinding balls in a ball mill To prevent the conditions leading to rod charge tangling, the length to diameter ratio is maintained at 14 to 16 Rod mills accept feed up to about 50 mm Autmatic Sand Blaster Machine Rod Mills Selection Criterion Autmatic Sand Blaster Machine Rod Mills Selection Criterion; 10 Amazing Automatic Firewood Processing 10112018 10 Amazing Automatic Firewood Processing Machine, Homemade Modern Wood Cutting Chainsaw Machines Thanks you for watching !Selection Of Rod MillsAG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill Because of the range of mill sizes available, AG/SAG milling can often be accomplished with fewer lines than in a conventional rod mill/ball mill circuit A diagram of types of AG/SAG AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator A rod with more guides on it will generally cast better and cost more than the same rod with fewer guides With more guides the rod will bend more consistently throughout its length, allowing it to utilize all the power for longer casts and fighting fish The Fuji Concept Guide System is the best example of this development on rods today CorkA Guide to Selecting the Right Rodmills in the older plants that had many mills in parallel In fact this is generally still the case in the multistream plants, where mill liner design and selection is only tackled on a cost consumables basis However, the gains to be had through good liner design and selection are just as great as on the large SAG millsThe Selection and Design of Mill Liners

Selection Of Material, Shape, And Manufacturing Process

Selection of Material, Shape and Manufacturing Process For a Connecting Rod ABSTRACT This activity centers on the courses of strength of materials and production design offered at a sophomore level Mechanical Engineering curriculum A connecting rod is one of the most mechanically stressed components in internal combustion enginesMay 24, 2016 Selection considerations 1 Choose the right cylinder type Two basic hydraulic cylinder designs for industrial applications are tierod and welded cylinders Tierod cylinders use highstrength threaded steel tie rods on the outside of the cylinder housing for additional strength and stability In the US, this is the most common cylinder typeTwelve tips for better cylinder selectionMay 27, 2014 For enthusiasts, technique specific gear is funto collect However, three rigs cover all thebasics:#1 6 1/2 or 7 MHF baitcaster for jigs, somesoft plastics and spinnerbaits#2 6 1/2 or 7 MM baitcaster for treble hooklures#3 7 MF spinning rod for lighter lures and avariety of techniquesRod Selection: The Basics Fishing Rods, Reels, Line, and Oct 03, 2010 Therefore if the tender had satisfied the selection criterion as to the content of the best practice documents there was nothing to prevent the Publications Office from taking into account in its award criteria the fact that the volume of best practice documents exceeded the maximum number of pages requested Mills Reeve Technology Our New cases on selection/award criteria Mills ReeveAug 04, 2018 As far as graphite rods, you can spend however much you want But, I think you can get a GREAT rod in the $130$300 range One thing to note is that generally the shorter a graphite rod gets the cheaper it gets So if you are trying to save a few bucks a 9 or 10 foot graphite rod is a good optionTop 9 Criteria to Evaluate When Choosing a Surf Rod The

Roller Drive Chain Selection and Engineering Information

232 renoldjeffrey • advancing chain technology 29 Roller Drive Chain Selection Technical Information Step 5: Select the Number of Teeth on the small sprocket The minimum number of teeth are found in the horsepower tables on pages 619 To determine, first calculate the Horsepower Table Rating (HP Table) from the followingSFX and Citation Linker Frequently asked questions concerning SFX; Electronic books The ebook database EBC; Audiovisual media; Research data; Alliance and national licencesSelection of Rod Mills Ball Mills and Regrind Mills Jul 19, 2020 Criteria for rodstring design Rod stress Rodstring selection and Mills on vibration effects of rod strings Fatigue of rods also was considered in 1940 These effects helped develop the Slonneger, Mills, and Langer formulas for rod loads A detailed discussion and development of these formulas is provided by ZabaSucker rods PetroWiki[Overflow Rod Mills Figure 1 Peripheral Discharge Rod Mills Figures 2 and 3 Compartment Mills Rod and Ball Figure 6 Ball Figure 6a Pebble Mill Figure 6b Overflow Ball Mills Figure 8 Diaphragm (Grate Discharge) Ball Mills Figure 9] I GENERAL MILL DESIGN A Liners The interior surface of grinding mills exposed to grinding media and/or the Selection Of Rod Mills, Ball Mills, Pebble Mills And Selection of Material, Shape and Manufacturing Process For a Connecting Rod ABSTRACT This activity centers on the courses of strength of materials and production design offered at a sophomore level Mechanical Engineering curriculum A connecting rod is one of the most mechanically stressed components in internal combustion enginesSelection Of Material, Shape, And Manufacturing Process

Grinding Media Growth Steel

Media to media contact for rods mills is linear rather than point to point (as with balls) and are much heavier The larger feed tends to separate rods at the feed end such that larger particles are preferentially abraded This leads to a narrower size distribution and significantly less slime compared to ball millsDec 09, 2014 Rod Selection Guide I’ve seen a lot of requests lately for a technique specific rod guide, so this is a general (and I stress the word general) guide to picking a technique specific rod Before we get into the details, let me first say, rod choice, while based Rod Selection Guide Fishing Rods, Reels, Line, and Knots DIES AND DIE SELECTION Die Metallurgy The basic physical properties of the die materials are controlled by the heat treating process and the composition of the die’s steel Carbon and Chromium The two key elements in our dies are carbon and chromium The carbon content of the steel affects the corrosion resistance and the wear resistance of DIES AND DIE SELECTION CPMMay 10, 2019 A combo is a matched rod and a reel set, configured for a specific type of fishing A wide selection is available, ranging from really basic up to top quality packages with excellent reels by Penn, Shimano and others Combos are ready to use, "out of the box" All you have to do is wind line onto the spool and add the terminal tackle of your Selecting a Rod and Reel Combo West MarineiMpOrTanT nOTe: The coupling selection criteria is intended for the determination of the coupling and style only It is also recommended that the system be analyzed for torsional and lateral stability using the specific coupling masselastic data available from Rexnord Omega Elastomeric Couplings Rexnord

New cases on selection/award criteria Mills Reeve

Oct 03, 2010 Therefore if the tender had satisfied the selection criterion as to the content of the best practice documents there was nothing to prevent the Publications Office from taking into account in its award criteria the fact that the volume of best practice documents exceeded the maximum number of pages requested Mills Reeve Technology Our Mainly used in large highpower and highspeed applications such as pumps, fans, compressors, main marine drives, extruders and rolling mills, shaft generators, boiler feed pumps, wire rod mills, starting generators, pump storage and starting applications (eg, blast furnaces)Medium Voltage Drives SINAMICS Electric Drives simply End mills, slot drills, routers, milling cutters, drill bits, Vbits and burrs what does it all mean? And which bit do I need for what job? For instance, which are the best end mills? and which is the best end mill for aluminium, and which are the best end mills for stainless steelEnd Mills The Essential Beginners GuideElectric Motor Selection and Sizing 332 Motor Sizing #2 • Each specific electric motor will have its own characteristic torquespeed “curve” Speed, ω Torque, τ AC Motor PMDC Motor Universal Motor Motor Sizing #3 Each type of load will have its own torque speed requirements Speed, ω Torque, τ Constant Pumps and Fans Viscous FrictionElectric Motor Selection and Sizing University of AlabamaSuch a material selection model was developed based on the desirable selection criteria including economic, environmental, societal, and technical issues for automotivebodies and was based on two ranking and evaluation methods The first one was the preference selection index (PSI) and the second one was the principal component analysis (PCA)Material Selection Chart an overview ScienceDirect Topics

Roller Drive Chain Selection and Engineering Information

232 renoldjeffrey • advancing chain technology 29 Roller Drive Chain Selection Technical Information Step 5: Select the Number of Teeth on the small sprocket The minimum number of teeth are found in the horsepower tables on pages 619 To determine, first calculate the Horsepower Table Rating (HP Table) from the following